-

- Environmentally friendly raw materials

- Effective thermal insulation properties

- Breathable thermal insulation material

- Anti-allergenic material – safe for health during installation and after installation

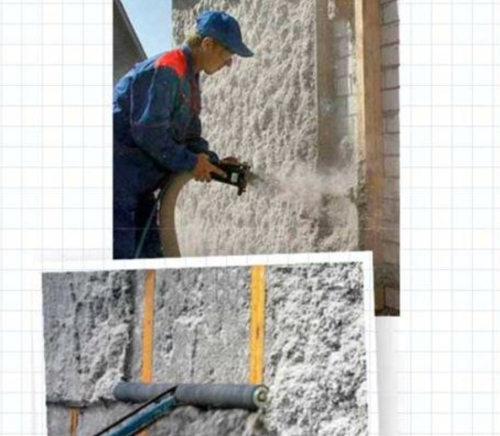

- Wide range of applications and different installation methods

- Economical application, as there is no material waste

- Fire-resistant and flame-retardant material

- Excellent sound insulation properties

- Rodents and pests avoid living in them

ECO ISOLATION

APPLICATION

BENEFITS

Make an Inquiry

If you have any questions or need additional information, please do not hesitate to contact us!